The crisis in Sircilla

The traditional powerlooms of Sircilla fall silent as they lose out to the modern, faster looms in other States.

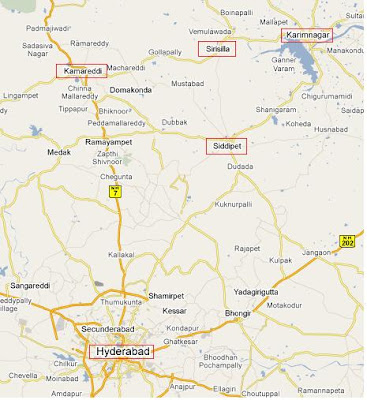

NOT very long ago, on a drive along the State highway from Hyderabad to the northern Telengana region you negotiated one bustling handloom centre after another, and an occasional powerloom complex. But all the hustle and bustle is now gone. There is hardly any activity. The looms have fallen silent. There is despair all around.

K. RAMESH BABU

A weaver working with four looms in Sircilla.

It is particularly stark in some pockets such as Sircilla, a major powerloom weaving centre in Karimnagar district, 65 km from the district headquarters of Karimnagar, where death hangs in the air. Suicides by weavers and powerloom owners are not uncommon.

Handloom weaving developed in Sircilla town in the 1920s, after some enterprising local people went to Solapur (now in Maharashtra) in search of work, learnt the art of weaving, came back and set up their own looms. It was a godsend for the people of the area with no alternative employment, and weaving quickly spread to some 50 villages around Sircilla town. Numerous allied activities developed. Over time, the skilled weavers of Sircilla developed unique designs and a niche market, mainly in Maharashtra, for their products. The looms gave employment to thousands of people, directly or indirectly.

The first signs of trouble came in the mid-1970s, when a large number of powerlooms were set up in Maharashtra and these began duplicating the unique designs of the Sircilla saris. The Sircilla handloom weavers could match neither the productivity nor the low costs of the Maharashtra powerlooms.

But they took up the challenge, and soon some 450 weavers jointly took a loan of Rs.1 crore from Andhra Bank and set up 3,000 powerlooms. They produced 25x25 counts cotton cloth (dyed in 40 colours) and 80x80 polyester cloth. Every loom, working two shifts, produced on an average 70 metres of cloth every day. This revived the weaving industry, which soon flourished with a market extending across the country, particularly Orissa, Gujarat, Maharashtra, Madhya Pradesh and Andhra Pradesh.

Around this time there was another development. Unwilling to concede the demands of their workers for higher wages, beedi unit owners of Maharashtra relocated to Sircilla, taking advantage of the connections some of them had with the weavers who went there either for work or to sell their products. Thus, while the Sircilla men moved to powerlooms, the women took to rolling beedis.

By 1990, the area had 10,000-12,000 powerlooms (owned by 800 people), providing reasonable livelihood to over 15,000 families. Some families also owned looms (one loom costs Rs.20,000), and wove cloth themselves without outside help. For instance, G. Ambadas, who owned four looms, employed about five persons and produced grey cotton cloth for the Maharashtra market. Now he works on only one loom, by himself. Says Ambadas: "My family barely survives. The cost of production has risen many times over in the last five years. My power bill, for instance, has increased from Rs.400 a month to Rs.1,800. The New Economic Policy is systematically wiping out artisans."

Roja Powerloom Society, with 32 looms and 31 members, stopped work in June 2000. Says its president P. Kumarayya: "From producing 100 metres of grey cotton cloth a day working two shifts in 1997, we produced 25 metres a day in 1999, and stopped completely last June." While some of its members have migrated, many have become head-load workers in and around Sircilla. Says Kumarayya: "Government help in subsidising inputs and in marketing our cloth is very important and urgent. I do not understand why the government is turning a blind eye to all the problems we have been facing in the last four years."

Allied activities, such as sizing and processing of yarn, have been closed, rendering 10,000 people jobless. Swarna Sizing and Processing Company, which employed 40 people in two shifts till 1999, has remained closed for the last two years. Dyavanapalli Narasaiyya, its owner, is now a headload worker in Sircilla town. Gundapalli Ramanujam, owner of a sizing unit which till 1998 employed 40 to 50 people, has kept himself out of sight for the last two years, unable to repay the term loan taken from the Andhra Pradesh State Finance Corporation. Such stories abound in and around Sircilla.

Mainly to blame is the Centre's liberalisation policy, introduced vigorously in 1991. Yarn prices spurted as the Centre started exporting in a frenzy, including huge quantities of cotton and yarn. The Centre also levied 9.25 per cent excise duty on cone yarn, pushing up yarn prices further. According to State Powerloom Minimum Wage Board member Konda Sankariah, in the last two years the price of a five-kg bale of 25-count cone yarn went up from Rs.300 to Rs.480. Also, according to Sircilla Municipal Chairperson A. Ravinder, "the mills produced only 40-65 counts yarn and not the 25 counts yarn we need." This pushed up yarn prices further. Clearly, the free play of market forces led to the differentiation among the various sections of the industry, pushing to the wall the poor and the vulnerable - a common fallout of a market-centred approach.

More recently, globalisation, the opening up of the economy and the removal of quantitative restrictions on some categories of goods, have led to dumping by China and Thailand, "making it impossible for us to sell our goods in the market".

The State government, on its part, raised power tariffs four times since 1995, as part of the reforms process. This 'shocked' the powerlooms as it pushed up weaving costs tremendously. The cottage industry - the powerloom industry is so classified - bore the brunt of the increase. According to Konda Sankariah, powerlooms were charged commercial rates. Erratic power supply also added to the problems.

The last straw was the removal of powerlooms from the small-scale sector as part of the Centre's liberalisation policies. Anyone could now set up a powerloom. Big producers, such as the Reliance and Mafatlal groups, entered the arena with modern jet and auto looms. The government also gave concessions for the import of second-hand machinery. The productivity of these modern powerlooms was much higher.

To aid these big players further, the Centre reduced the Customs duty on modern powerlooms from 15 per cent to 5 per cent and also provided them a 50 per cent subsidy on machinery under the Technology Upgradation Fund Scheme (TUFS). Many big and modern powerlooms in Maharashtra have set up composite looms and adopted an integrated production system, incorporating all allied activities such as warping, spinning, weaving and dyeing,

The Sircilla powerlooms could not even dream of competing with these modern looms in terms of price, quantity or quality. Sales dropped and stocks mounted, as did the interest outstandings on bank loans. According to Sircilla Powerloom and the Handloom Cloth Merchants Association founder-president Rudra Sankariah, materials worth over Rs.2 crores have been lying in godowns for the last two years.

The problems of the weaving industry have often been seen as an issue of handlooms versus powerlooms. This is no longer valid. With liberalisation, globalisation and structural adjustment of the economy, the issue is now one of the small and vulnerable versus the big and strong. The market differentiation is sharp and clear.

According to P. Premchand, president of Krushi, a non-governmental organisation, the problem of increased cost of production was compounded by the simultaneous fall in product prices, and the sharp increase in consumption costs. Everything worked against the traditional powerloom sector.

Worse, the weavers could not benefit from any government scheme. For instance, the Debt Relief Fund of Rs.10,000 announced by the government in 1989 applies only to handloom weavers. The Sircilla weavers are also not eligible for assistance to modernise their looms under the TUFS as it does not cover cottage industries. The family of the weaver who commits suicide is not even eligible for an ex gratia payment. Says Karimnagar Collector Debabratha Kantha: "It should not be given as it would become an incentive for weavers to commit suicide."

The traditional powerlooms of Sircilla fall silent as they lose out to the modern, faster looms in other States.

NOT very long ago, on a drive along the State highway from Hyderabad to the northern Telengana region you negotiated one bustling handloom centre after another, and an occasional powerloom complex. But all the hustle and bustle is now gone. There is hardly any activity. The looms have fallen silent. There is despair all around.

K. RAMESH BABU

A weaver working with four looms in Sircilla.

It is particularly stark in some pockets such as Sircilla, a major powerloom weaving centre in Karimnagar district, 65 km from the district headquarters of Karimnagar, where death hangs in the air. Suicides by weavers and powerloom owners are not uncommon.

Handloom weaving developed in Sircilla town in the 1920s, after some enterprising local people went to Solapur (now in Maharashtra) in search of work, learnt the art of weaving, came back and set up their own looms. It was a godsend for the people of the area with no alternative employment, and weaving quickly spread to some 50 villages around Sircilla town. Numerous allied activities developed. Over time, the skilled weavers of Sircilla developed unique designs and a niche market, mainly in Maharashtra, for their products. The looms gave employment to thousands of people, directly or indirectly.

The first signs of trouble came in the mid-1970s, when a large number of powerlooms were set up in Maharashtra and these began duplicating the unique designs of the Sircilla saris. The Sircilla handloom weavers could match neither the productivity nor the low costs of the Maharashtra powerlooms.

But they took up the challenge, and soon some 450 weavers jointly took a loan of Rs.1 crore from Andhra Bank and set up 3,000 powerlooms. They produced 25x25 counts cotton cloth (dyed in 40 colours) and 80x80 polyester cloth. Every loom, working two shifts, produced on an average 70 metres of cloth every day. This revived the weaving industry, which soon flourished with a market extending across the country, particularly Orissa, Gujarat, Maharashtra, Madhya Pradesh and Andhra Pradesh.

Around this time there was another development. Unwilling to concede the demands of their workers for higher wages, beedi unit owners of Maharashtra relocated to Sircilla, taking advantage of the connections some of them had with the weavers who went there either for work or to sell their products. Thus, while the Sircilla men moved to powerlooms, the women took to rolling beedis.

By 1990, the area had 10,000-12,000 powerlooms (owned by 800 people), providing reasonable livelihood to over 15,000 families. Some families also owned looms (one loom costs Rs.20,000), and wove cloth themselves without outside help. For instance, G. Ambadas, who owned four looms, employed about five persons and produced grey cotton cloth for the Maharashtra market. Now he works on only one loom, by himself. Says Ambadas: "My family barely survives. The cost of production has risen many times over in the last five years. My power bill, for instance, has increased from Rs.400 a month to Rs.1,800. The New Economic Policy is systematically wiping out artisans."

Roja Powerloom Society, with 32 looms and 31 members, stopped work in June 2000. Says its president P. Kumarayya: "From producing 100 metres of grey cotton cloth a day working two shifts in 1997, we produced 25 metres a day in 1999, and stopped completely last June." While some of its members have migrated, many have become head-load workers in and around Sircilla. Says Kumarayya: "Government help in subsidising inputs and in marketing our cloth is very important and urgent. I do not understand why the government is turning a blind eye to all the problems we have been facing in the last four years."

Allied activities, such as sizing and processing of yarn, have been closed, rendering 10,000 people jobless. Swarna Sizing and Processing Company, which employed 40 people in two shifts till 1999, has remained closed for the last two years. Dyavanapalli Narasaiyya, its owner, is now a headload worker in Sircilla town. Gundapalli Ramanujam, owner of a sizing unit which till 1998 employed 40 to 50 people, has kept himself out of sight for the last two years, unable to repay the term loan taken from the Andhra Pradesh State Finance Corporation. Such stories abound in and around Sircilla.

Mainly to blame is the Centre's liberalisation policy, introduced vigorously in 1991. Yarn prices spurted as the Centre started exporting in a frenzy, including huge quantities of cotton and yarn. The Centre also levied 9.25 per cent excise duty on cone yarn, pushing up yarn prices further. According to State Powerloom Minimum Wage Board member Konda Sankariah, in the last two years the price of a five-kg bale of 25-count cone yarn went up from Rs.300 to Rs.480. Also, according to Sircilla Municipal Chairperson A. Ravinder, "the mills produced only 40-65 counts yarn and not the 25 counts yarn we need." This pushed up yarn prices further. Clearly, the free play of market forces led to the differentiation among the various sections of the industry, pushing to the wall the poor and the vulnerable - a common fallout of a market-centred approach.

More recently, globalisation, the opening up of the economy and the removal of quantitative restrictions on some categories of goods, have led to dumping by China and Thailand, "making it impossible for us to sell our goods in the market".

The State government, on its part, raised power tariffs four times since 1995, as part of the reforms process. This 'shocked' the powerlooms as it pushed up weaving costs tremendously. The cottage industry - the powerloom industry is so classified - bore the brunt of the increase. According to Konda Sankariah, powerlooms were charged commercial rates. Erratic power supply also added to the problems.

The last straw was the removal of powerlooms from the small-scale sector as part of the Centre's liberalisation policies. Anyone could now set up a powerloom. Big producers, such as the Reliance and Mafatlal groups, entered the arena with modern jet and auto looms. The government also gave concessions for the import of second-hand machinery. The productivity of these modern powerlooms was much higher.

To aid these big players further, the Centre reduced the Customs duty on modern powerlooms from 15 per cent to 5 per cent and also provided them a 50 per cent subsidy on machinery under the Technology Upgradation Fund Scheme (TUFS). Many big and modern powerlooms in Maharashtra have set up composite looms and adopted an integrated production system, incorporating all allied activities such as warping, spinning, weaving and dyeing,

The Sircilla powerlooms could not even dream of competing with these modern looms in terms of price, quantity or quality. Sales dropped and stocks mounted, as did the interest outstandings on bank loans. According to Sircilla Powerloom and the Handloom Cloth Merchants Association founder-president Rudra Sankariah, materials worth over Rs.2 crores have been lying in godowns for the last two years.

The problems of the weaving industry have often been seen as an issue of handlooms versus powerlooms. This is no longer valid. With liberalisation, globalisation and structural adjustment of the economy, the issue is now one of the small and vulnerable versus the big and strong. The market differentiation is sharp and clear.

According to P. Premchand, president of Krushi, a non-governmental organisation, the problem of increased cost of production was compounded by the simultaneous fall in product prices, and the sharp increase in consumption costs. Everything worked against the traditional powerloom sector.

Worse, the weavers could not benefit from any government scheme. For instance, the Debt Relief Fund of Rs.10,000 announced by the government in 1989 applies only to handloom weavers. The Sircilla weavers are also not eligible for assistance to modernise their looms under the TUFS as it does not cover cottage industries. The family of the weaver who commits suicide is not even eligible for an ex gratia payment. Says Karimnagar Collector Debabratha Kantha: "It should not be given as it would become an incentive for weavers to commit suicide."

No comments:

Post a Comment